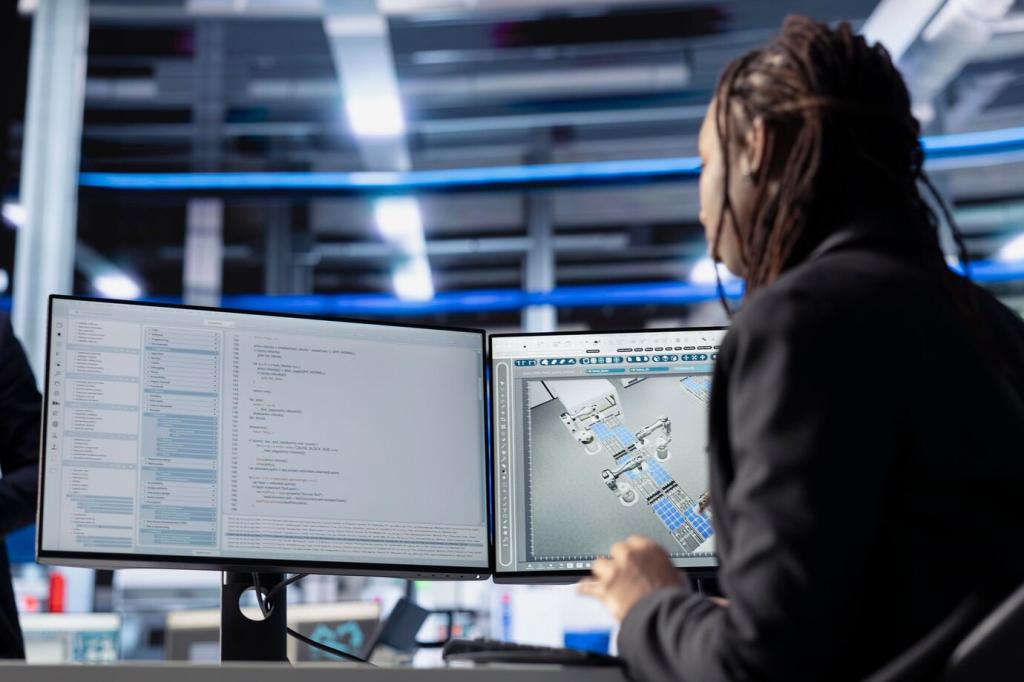

Map the Current State Before You Automate

Walk the floor with fresh eyes and a stopwatch. Trace fast movers, dead stock, and the awkward workarounds people use. Catalog exceptions honestly; automation loves clarity but trips over hidden, unspoken process debt.

Map the Current State Before You Automate

Use simple apps or camera time studies to capture cycle times, travel paths, and queue delays. Visualize hotspots on a heatmap. Invite operators to narrate where reality diverges from standard work instructions, revealing true improvement opportunities.