Best Practices for Warehouse Inventory Automation

Chosen theme: Best Practices for Warehouse Inventory Automation. Welcome to a practical, human-centered guide to streamlining your warehouse—where data discipline, right-sized tech, and frontline wisdom come together. Share your challenges, subscribe for fresh insights, and help shape our next deep-dive.

Data Foundations: Barcodes, SKUs, and Master Data

Choose consistent symbologies, define quiet zones, and standardize label placement at receiving and storage. GS1-128 for cases, ITF-14 for corrugate, and clear human-readable text reduce scans and errors. We saw mis-scans drop dramatically after moving labels from seams. What barcode headaches haunt your shifts?

Data Foundations: Barcodes, SKUs, and Master Data

Consolidate duplicates, align units of measure, and clarify inner, case, and pallet relationships. Automation falters when two SKUs describe the same item. A mid-sized distributor cut replenishment errors by forty percent after rationalizing UOM conversions. Share your toughest SKU tangle—we might feature it in a future post.

Selecting a WMS/WES for Your Size

List must-have workflows—receiving, directed putaway, wave planning, replenishment, and cycle counting—then test with real scenarios. Cloud options speed deployment; on-prem can suit specialized compliance. Avoid bells you will not ring. Tell us your top three must-haves and we will compare platforms in a future piece.

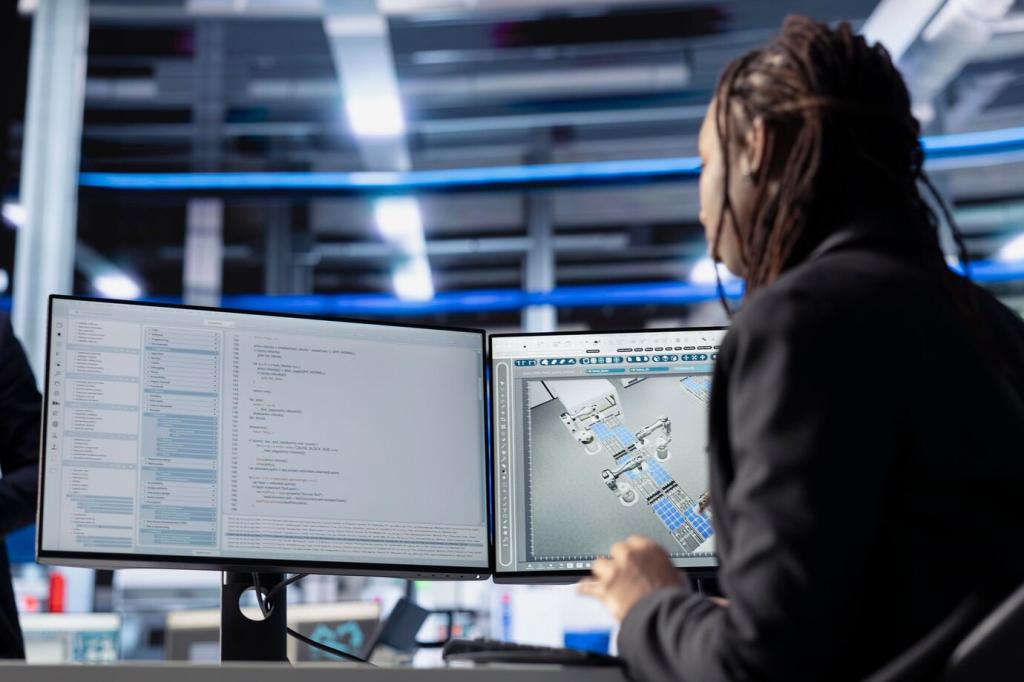

APIs, Middleware, and ERP Sync

Stable automation hinges on reliable data flow. Prefer event-driven APIs, resilient message queues, and clear error handling. Mirror item masters and inventory balances with timestamps. One client cut reconciliation time by eighty percent using webhooks and retry logic. Comment if your stack needs an integration health check.

Mobile Scanning and Voice Picking

Handheld scanners and voice-directed workflows boost accuracy and speed with minimal disruption. We routinely see twenty to thirty percent productivity gains and near-perfect lot captures when prompts are concise. Test devices in cold rooms and high-gloss aisles. Share your favorite device model and why operators trust it.

Physical Layout and Slotting Optimization

Rank SKUs by velocity and place A items in golden zones near pick paths at ergonomic heights. Re-slot seasonally and after promotions. One team shaved six seconds per line simply by rotating five high-mix bays. Which slotting rule has saved you the most footsteps this quarter?

Physical Layout and Slotting Optimization

Define clear zones for fast movers, bulky items, and value-added services, and favor one-way aisles to reduce congestion. Stagger pick waves to balance traffic. Share your aisle width sweet spot and any clever signage that keeps carts and AMRs flowing smoothly.

Lean Operations and Change Management

Choose one area, define success criteria, and time-box the pilot. Measure baseline versus post-implementation and hold a retrospective with operators. When a cart-pick pilot hit ninety-nine point seven percent accuracy, rollout was a team decision. Share your pilot plan and we will help pressure-test it.

Lean Operations and Change Management

Create clear, illustrated SOPs and pair new tech with hands-on practice. Layer microlearning videos and quick reference cards at stations. Rotate mentors so tribal knowledge spreads. What training format actually sticks in your warehouse? Drop a note and we will swap templates.

Focus on pick accuracy, order cycle time, lines per labor hour, dock-to-stock, inventory accuracy, and on-time ship. Visualize trends and annotate changes after upgrades. Ask teams which KPI they can move this week. Comment with your top three and why they matter most.

Metrics, Dashboards, and Continuous Improvement

Go see the work. When a spike appears, follow a real order through each step and ask five whys. We once traced mis-picks to a faded bin label in low light. What simple fix delivered your biggest win? Share the story.